K- SLUMP TEST FOR WORKABILITY OF CONCRETE

The slump test is the most popular to find the workability of freshly mixed concrete. But testing the sample batch to batch with Slump test takes more time and effort.

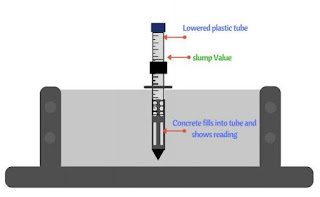

K slump test is an instant and direct test where slump value is calculated within a minute. It has a tester that is inserted in freshly mixed concrete to determine the slump value of concrete.

The K Slump test is covered by ASTM C 1362.

Apparatus of K-Slump Test

The K slump tester is made with chrome plated steel, Aluminum, and plastic. The upper part is made of Plastic serves as a handle, and the lower part made of the chrome plated steel tube is used for testing.

The round chrome plated steel is hollow and has an external dia of the 1.9cm and internal diameter of 1.6cm. The length of the tube is 25cm, and it also includes the solid cone at the bottom which facilitates inserting the tube into the fresh concrete.

Middle part of K Slump Tester

The disc floater of dia 6cm and thickness 0.24cm divides the tube into two parts. The disc is used to prevent the k slump tester from sinking into the fresh concrete exceeding the preselected level.

Upper part of K Slump tester

The upper part of K slump tester has a hollow plastic tube of dia 6cm, and 0.24cm thickness which is graduated with centimeter scale. The bottom portion of tube has the aluminum cap 3 cm diameter and 2.25 cm long which has a little Hole and a screw that can be used to set and adjust the reference zero of the apparatus.The Hollow plastic rod can move freely inside the chrome plated tube through the disc. The rod is also provided with the small pin which is used to support the measuring tube at the beginning of the test. (Both tubes are hollow)

Procedure of K Slump Test

1. Wet the tester and clean it with a cloth.

2. Raise the plastic tube let it sit on the pin support.

No comments:

Post a Comment